Formability, Mechanical and Chemical Properties Assessment for High Strength AA7075 Subjected to Annealing Heat Treatment

DOI:

https://doi.org/10.51173/jt.v5i1.1107Keywords:

Formability, Mechanical Properties, Annealing Heat Treatment, Corrosion TestAbstract

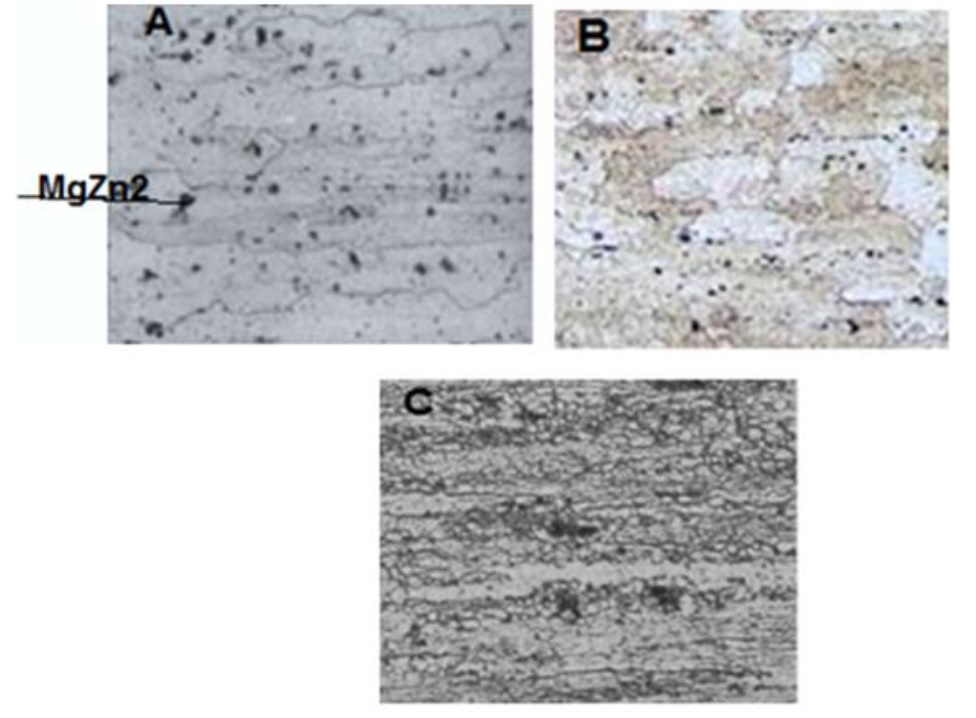

The current study examined how the annealing process affected the formability, mechanical and chemical characteristics of 7075 alloy. The formability was achieved during the bending test. Tensile, hardness, microstructure and corrosion tests represent mechanical and chemical properties. The test specimens for each test were prepared then followed by annealing heat treatment by heating them to 200 and 300°C in an electrical furnace for two hours. Then, the specimens were allowed to cool in the furnace to a room temperature. The results indicate that the tensile strength and hardness were decreased for about 50%. Bending strength was increased by approximately 30%, where the specimens bent at a very high angle without cracking or breaking in comparison to base metal. Annealing heat treatment with a proper selected procedures and temperatures was able to stabilize the microstructure and release the second phase precipitate particles. Annealing process contributed in improving formability, ductility and corrosion resistance of the Al 7075 alloy.

Downloads

References

A.D. Assi., "A new Track of Fatigue crack growth in Aluminum Alloy (2219) under Cyclic Stresses." Journal of Techniques 2.4. 2020.

H. M. Mahan, S. V. Konovalov, I.V. Panchenko, & D.D. Pashkova, Study of the properties and structure of aluminum matrix composites reinforced with TiO2 particles. Polzunovskiyvеstnik, 4(2), 7-13,2022.

S. K. Panigrahi and R. Jayaganthan, "Effect of Annealing on Thermal Stability, Precipitate Evolution, and Mechanical Properties of Cryorolled Al 7075 Alloy", Metallurgical and Materials Transactions A, November 28, 2010.

A.C.Umamaheswer Rao1,V. Vasu1, M. Govindaraju, and K.V. Sai Srinadh, "Influence of Cold Rolling and Annealing on the Tensile Properties of the Aluminum 7075 Alloy " International Conference on Advances in Manufacturing and Materials Engineering AMME 2014, Proce. Materials Science, vol. 5, 2014, pp. 86-95.

A. Fallahi, H. Hosseini-Tudeshky, S. M. Ghalehbandi, "Effect of heat treatment on mechanical properties of ECAPed 7075 aluminum alloy", Article in Advanced Materials Research, 2013. DOI:10.4028/www.scientific.net/AMR.829.62 CITATIONS 4.

M. Tajally, Z. Huda and H. H. Masjuki, "Effect of Cold Rolling on Bending and Tensile Behaviour of 7075 Aluminum alloy", Journal of Applied Sciences, vol. 9, No.21, pp. 3883-3893, 2009.

F. B. Darsono1 and S. T. Koin, "The Effect of T6 Heat Treatment on 7075 Aluminum on its Hardness and Tensile Strength" IOP Conf. Series: Materials Science and Engineering 1096 (2021) 012042 IOP Publishing doi:10.1088/1757-899X/1096/1/012042.

A. D. Isadarea, B. Aremob, M. O. Adeoyec, "Effect of Heat Treatment on Some Mechanical Properties of 7075 Aluminum Alloy" Materials Research, vol. 16, No. 1, pp. 190-194, 2013. DOI:10.1590/S1516-14392012005000167.

Y. H. Zhao, X. Z. Liao and Y. T. Zhua, "Enhanced mechanical properties in ultrafine grained 7075Al alloy", J. Mater. Res., vol. 20, No. 2, pp. 288-290, Feb. 2005.

M. Zuo, M. Sokoluk, C. Cao, J. Yuan, S. Zheng & X. Li, "Microstructure Control and Performance Evolution of Aluminum Alloy 7075 by Nano-Treating", Scientific report, published in on line 23 July 2019.

P. V. Kumar, G. M. Reddy, K. Srinivasa Rao, "Microstructure and pitting corrosion of armor grade AA7075 aluminum alloy friction stir weld nugget zone e Effect of post weld heat treatment and addition of boron carbide" www.elsevier.com/locate/dt Defense Technology 11, 2015, pp. 166-173.

H. William, Properties and Selection: Non-Ferrous Alloys and Pure Materials, Metal Handbook, vol.9, 1985.

N. Seemuang, S. Panich, and T. Slatter, "Bendability evaluation of sheet metals in three-point bending test by using acoustic emission features", The Journal of Applied Science, vol. 16, No. 2, pp. 15-22, 2017. DOI:10.14416/j.appsci.2017.12.001.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Naseer Malik Abbas, Zahraa Thamer Abdulwahid, Asmaa Ali Hussien, S.V. Konovalov, Hamid M. Mahan

This work is licensed under a Creative Commons Attribution 4.0 International License.