Assessment of the Ultrasonic Machine for Surface Finishing of 3D-Printed Cobalt-Chromium Alloy by Selective Laser Melting Technology

DOI:

https://doi.org/10.51173/jt.v4i33.727Keywords:

Cobalt-chromium alloys, Ultrasonic vibration, Surface roughness, FinishingAbstract

The selective laser melting (SLM) system reaches the status of a contender with the traditional casting of dental alloys, with the essential drawback that it is conducive to roughness, making surfaces difficult to finish by the conventional method. Ultrasonic machines (USM) are instrumentally sensible for processes involving metal surface adjustments.

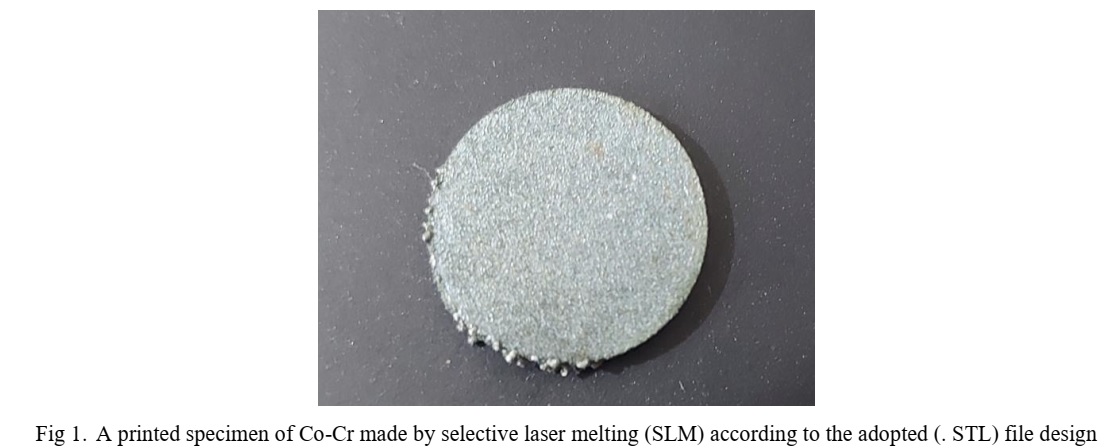

This study aims to assess the surface roughness for SLM by using USM instead of conventional finishing. The discs of cobalt chromium alloy were printed by SLM (n = 20) and evenly divided into two groups: one for finishing in compliance with the manufacturer's standard procedure, and the other for employing USM. The specimens were evaluated using the Surface Roughness Test, and the data was analyzed using the t-test.

Highly significant differences were found at P < 0.01. Furthermore, the mean value accounted for a low level of readings (Ra) in the USM group, which amounted to 1.707, and with regard to the control group, it was 4.539. Ultrasonic finishing processes promote the competence of the finishing procedure and improve the surface quality for dental cobalt chromium alloys that are printed by SLM technology.

Downloads

References

Baciu, E.R., Cimpoeșu, R., Vițalariu, A., Baciu, C., Cimpoeșu, N., Sodor, et al., "Surface Analysis of 3D (SLM) Co–Cr–W Dental Metallic Materials", Applied Sciences, vol. 11, No. 1, pp 255, 2020.

Øilo, M., Nesse, H., Lundberg, O.J. and Gjerdet, N.R., "Mechanical properties of cobalt-chromium 3-unit fixed dental prostheses fabricated by casting, milling, and additive manufacturing," The Journal of Prosthetic Dentistry, Vol. 120, Issue 1, PP156.e1-156.e7, 2018.

Barraclough, O., Gray, D., Ali, Z. and Nattress, B."Modern Partial Dentures-Part 1: Novel Manufacturing Techniques," British Dental Journal, vol. 230, No. 10, pp. 651-657, 2021.

Zhang, D., Yu, J., Li, H., Zhou, X., Song, C., Zhang, C., et al., "Investigation of laser polishing of four selective laser melting alloy samples". Applied Sciences, Vol. l10, No. 3, pp. 760, 2020.

Presotto, A.G.C., Cordeiro, J.M., Presotto, J.G.C., Rangel, E.C., da Cruz, N.C., et al.,"Feasibility of 3D printed Co–Cr alloy for dental prostheses applications," Journal of Alloys and Compounds, Vol. 862, PP158171, 2021.

Sidambe, A.T., "Effects of build orientation on 3D-printed Co-Cr-Mo: surface topography and L929 fibroblast cellular response." The International Journal of Advanced Manufacturing Technology, Vol. 99, No. 1, pp. 861–880, 2018.

Finazzi, V., Demir, A.G., Biffi, C.A., Migliavacca, F., Petrini, L., et al., "Design and functional testing of a novel balloon-expandable cardiovascular stent in CoCr alloy produced by selective laser melting." Journal of Manufacturing Processes, Vol. 55, PP.161-173, 2020.

Fashanu, F.F., Marcellin-Little, D.J. and Linke, B.S.,"Review of Surface Finishing of Additively Manufactured Metal Implants." In: International Manufacturing Science and Engineering Conference, American Society of Mechanical Engineers, Vol. 84256, p. V001T03A013, 2020.

Basha, S.M., Bhuyan, M., Basha, M.M., Venkaiah, N. and Sankar, M.R., "Laser polishing of 3D printed metallic components: a review on surface integrity." Materials Today: Proceedings, Vol. 26, pp. 2047–2054, 2020.

Yung, K.C., Xiao, T.Y., Choy, H.S., Wang, W.J. and Cai, Z.X.,"Laser polishing of additive manufactured CoCr alloy components with complex surface geometry." Journal of Materials Processing Technology, Vol. 262, pp. 53-64, 2018.

Hegade, T., RK, J., Nagarjuna, L.R., Babu, P.P., Srikanth, A.K. and Nanjundeswaraswamy, T.S., "Process Characteristics in Ultrasonic Machining." International Journal of Engineering Research & Technology (IJERT) 8, issue 11, Vol.8, 2019.

O’Toole, L., Kang, C. and Fang, F., "Advances in rotary ultrasonic-assisted machining." Nanomanufacturing and Metrology, vol. 3, issue 1, pp. 1–25, 2020.

Wang, J., Zhu, J. and Liew, P.J., "Material removal in ultrasonic abrasive polishing of additive manufactured components." Applied Sciences, Vol. 9, no. 24, pp. 5359, 2019.

Malygin, V.I., Kuvaldin, Y.I., Oblovatskaya, N.S., Lapteva, E.N. and Slutskov, V.A., "Influence of Ultrasonic Finishing on the Surface Roughness of Tool-Steel Components." Russian Engineering Research, Vol. 41, No. 3, pp. 222-226, 2021.

BEGO. (2020). CAD/CAM-manufactured restorations from WIRONIUM® RP. Available: https://www.bego.com/fileadmin/user_downloads/Mediathek/Medical/Werkstoffe/WIRONIUM-RP/EN/me_800403_0001_vh_en.pdf

Moslehifard, E., Seyyedashrafi, M.M. and Khosronejad, N.,"Evaluation of Surface Roughness of a Ni-Cr Alloy Treated with the Nd/YAG Laser and the Sandblast Technique." Journal of Lasers in Medical Sciences, Vol.12, pp. e69-e69, 2021.

ASTM D7127 -. 17(2020)., Standard Test Method for Measurement of Surface Roughness of Abrasive Blast Cleaned Metal Surfaces Using a Portable Stylus Instrument [Online]. (2020) (Accessed March 18, 2020).

Cortés-Sandoval, G., Martínez-Castañón, G.A., Patiño-Marín, N., Martínez-Rodríguez, P.R. and Loyola-Rodríguez, J.P., "Surface roughness and hardness evaluation of some base metal alloys and denture base acrylics used for oral rehabilitation." Materials Letters., Vol.144, pp.100-105, 2015.

Gora, W.S., Tian, Y., Ardron, M., Prangnell, P., Weston, N.J. and Hand, D.P., "Laser polishing to improve the surface quality of CoCr and Ti6AL4V additively manufactured parts," In International Congress on Applications of Lasers & Electro-Optics, October, Vol. 2017, No. 1, pp. 1405, 2017.

Taylor, R., Maryan, C. and Verran, J.,"Retention of oral microorganisms on cobalt-chromium alloy and dental acrylic resin with different surface finishes," The Journal of prosthetic dentistry, Vol.80, No.5, pp.592-597, 1998.

Ma, C., Dong, Y. and Ye, C.,"Improving surface finish of 3D-printed metals by ultrasonic nanocrystal surface modification," Procedia Cirp, Vol.45, pp.319–322, 2016.

Teramachi, A. and Yan, J., "Improving the surface integrity of additive-manufactured metal parts by ultrasonic vibration-assisted burnishing." Journal of Micro and Nano-Manufacturing, Vol. 7, Issue 2, 2019.

Huuki, J. and Laakso, S.V., "Integrity of surfaces finished with ultrasonic burnishing.” Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture,Vol 227 Issue1, pp.45-53, 2013.

Malygin, V.I., Kuvaldin, Y.I., Oblovatskaya, N.S., Lapteva, E.N. and Slutskov, V.A., " Influence of Ultrasonic Finishing on the Surface Roughness of Ship Components, " Russian Engineering Research, Vol. 41, No. 3, pp. 222–226, 2021.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Mahmood Abdulla Ahmad, Israa Mohammed Hummudi

This work is licensed under a Creative Commons Attribution 4.0 International License.