Design and Optimization of Iron Cow Stem with Flaps by Finite Element Method and Genetic Algorithm

DOI:

https://doi.org/10.51173/jt.v6i3.1930Keywords:

Stress, Finite Element, Plow, Genetic Algorithm, Neural NetworkAbstract

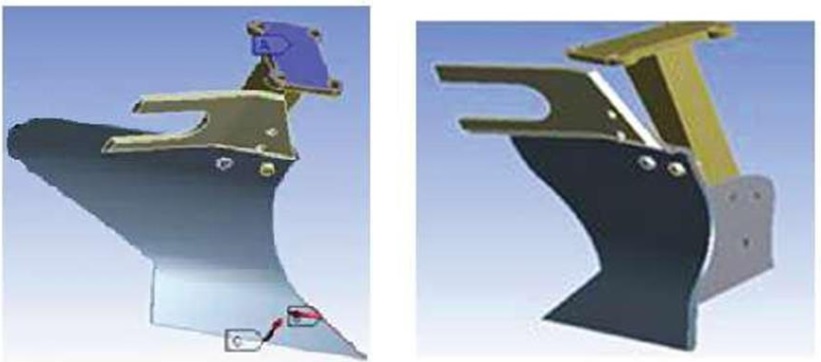

Reversible plows are one of the important and efficient tools in primary tillage, which are affected by many dynamic loads. These tools are damaged in different working conditions, and they are damaged from the stem area. For this reason, in this research, a method based on the finite element method and genetic algorithm was presented to optimize the reversible plow shaft. In this research, two parameters of cross-sectional area and stem curvature were investigated as independent variables. A total of 24 different models for the plow shaft were designed in SolidWorks software, FEM software and used Iron Cow Stem. Then, the different designs of the stem in the environment of the abacus were loaded and stress free occurred in them and were eliminated. Then, using an artificial neural network, a model was presented to estimate the von Mises tension based on the information related to the cross-sectional area and stem curvature, and this model was able to estimate the maximum von Mises tension with an accuracy of 99%. Then the mentioned model was linked with the genetic algorithm and it was used to optimize the plow shaft. After selecting the optimized model through the genetic algorithm, the plow shaft was designed again and the tireless stress that occurred in it under the same loading conditions as the previous conditions was eliminated. The results showed that the amount of maximum stress in this model decreased by 6% compared to the previous models and the best stem designs is (Stress (MPa) VonMises=295.2).

Downloads

References

Y. Liu et al., “Bionic design of thin-walled tubes inspired by the vascular structure of bamboo,” Thin-Walled Structures, vol. 186, p. 110689, May 2023, doi: 10.1016/j.tws.2023.110689.

Q. Zhang et al., “Advanced biomaterials for repairing and reconstruction of mandibular defects,” Materials Science and Engineering: C, vol. 103, p. 109858, Oct. 2019, doi: 10.1016/j.msec.2019.109858.

H. Quan, A. Pirosa, W. Yang, R. O. Ritchie, and M. A. Meyers, “Hydration-induced reversible deformation of the pine cone,” Acta Biomaterialia, vol. 128, pp. 370–383, Jul. 2021, doi: 10.1016/j.actbio.2021.04.049.

R. Sarkar, B. Chen, M. E. Fitzpatrick, D. Fabijanic, and T. Hilditch, “Additive manufacturing-based repair of IN718 superalloy and high-cycle fatigue assessment of the joint,” Additive Manufacturing, vol. 60, p. 103276, Dec. 2022, doi: 10.1016/j.addma.2022.103276.

A. P. More, “Flax fiber–based polymer composites: a review,” Advanced Composites and Hybrid Materials, vol. 5, no. 1, pp. 1–20, May 2021, doi: 10.1007/s42114-021-00246-9.

X.-M. Chen, X. Wang, and Z. Hou, “Editorial: MSC-derived exosomes in tissue regeneration,” Frontiers in Cell and Developmental Biology, vol. 11, Sep. 2023, doi: 10.3389/fcell.2023.1293109.

I. A. Alhassan, “Land-Use Conflicts between Settler Farmers and Nomadic Fulani Herdsmen in the Kwahu North District, Ghana,” Contemporary Journal of African Studies, vol. 4, no. 2, p. 127, Jun. 2017, doi: 10.4314/contjas. v4i2.5. [Online]. Available, doi:10.4314/contjas. v4i2.5

M. Dettinger, A. Wilson, and G. McGurk, “Keeping Water in Climate-Changed Headwaters Longer,” San Francisco Estuary and Watershed Science, vol. 21, no. 4, Dec. 2023, doi: 10.15447/sfews.2023v21iss4art1.

S. Duncan Stephens, E. J. Flaherty, W. J. Sutton, W. N. MacDonald, and B. J. Shelp, “Further optimization of macronutrient delivery for subirrigated greenhouse-grown chrysanthemums: calcium and magnesium,” Canadian Journal of Plant Science, vol. 101, no. 1, pp. 129–134, Feb. 2021, doi: 10.1139/cjps-2020-0117.

T. Knežić, L. Janjušević, M. Djisalov, S. Yodmuang, and I. Gadjanski, “Using Vertebrate Stem and Progenitor Cells for Cellular Agriculture, State-of-the-Art, Challenges, and Future Perspectives,” Biomolecules, vol. 12, no. 5, p. 699, May 2022, doi: 10.3390/biom12050699.

H. A. Ariyanta, S. Chodijah, F. Roji, A. Kurnia, and D. O. B. Apriandanu, “The role of Andrographis paniculata L. modified nanochitosan for lamivudine encapsulation efficiency enhancement and in vitro drug release study,” Journal of Drug Delivery Science and Technology, vol. 67, p. 103016, Jan. 2022, doi: 10.1016/j.jddst.2021.103016.

F. V. Hladkykh, “Macroscopic assessment of protective effect of cryopreserved placenta extract in ibuprofen-induced gastroenterocolonopathy,” GASTROENTEROLOGY, vol. 55, no. 3, pp. 172–179, Jan. 2022, doi: 10.22141/2308-2097.55.3.2021.241587.

X. Li, H. Shi, K. Pan, M. Dai, W. Wei, and X. Liu, “Improved biocompatibility and antibacterial property of zinc alloy fabricated with γ-polyglutamic acid-g-dopamine/copper coatings for orthopedic implants,” Progress in Organic Coatings, vol. 173, p. 107215, Dec. 2022, doi: 10.1016/j.porgcoat.2022.107215.

A. Wei, R. Al-Ameri, M. Y. J. Tan, Y.-C. Koay, and X. Hu, “Effectiveness of carbon fiber-reinforced polymer as a triple-functional material for sustainable protection of reinforced concrete structures,” Innovative Infrastructure Solutions, vol. 8, no. 6, May 2023, doi: 10.1007/s41062-023-01139-0.

Y. R. Kang, “Rewriting The Wonderful Wizard of Oz: African American Musical Theatre and The Wiz Live!,” The Journal of Modern English Drama, vol. 35, no. 2, pp. 5–30, Aug. 2022, doi: 10.29163/jmed.2022.8.35.2.5.

M. Lendraitis, “Investigation of performance gains on a sailplane with morphing wing trailing edge,” Mechanics, vol. 25, no. 4, pp. 299–303, Aug. 2019, doi: 10.5755/j01.mech.25.4.22325.

Z. Su and L. Shao, “A three-dimensional slope stability analysis method based on finite element method stress analysis,” Engineering Geology, vol. 280, p. 105910, Jan. 2021, doi: 10.1016/j.enggeo.2020.105910.

K. Jegadeesan and S. Datta, “Design of laminated composite plate for optimum ballistic impact resistance: A finite element approach,” Materials Today: Proceedings, vol. 68, pp. 2493–2497, 2022, doi: 10.1016/j.matpr.2022.09.182.

Yu, Hui, Lingling Zheng, Jikuan Qiu, Jiayue Wang, Yaoke Xu, Baoshi Fan, Rui Li, Junxiu Liu, Chao Wang, and Yubo Fan. "Mechanical property analysis and design parameter optimization of a novel nitinol nasal stent based on numerical simulation." Frontiers in Bioengineering and Biotechnology 10, 1064605, 2022, doi:10.3389/fbioe.2022.1064605.

Ge-Zhang, Shangjie, Mingbo Song, Zehang Huang, Maodan Li, and Liqiang Mu. "Comparison and optimization: research on the structure of the PET bottle bottom based on the finite element method." Polymers 14, no. 15, 3174, 2022, doi:10.3389/fbioe.2022.1064605.

T. He, “Extending the cell‐based smoothed finite element method into strongly coupled fluid–thermal–structure interaction,” International Journal for Numerical Methods in Fluids, vol. 93, no. 4, pp. 1269–1291, Oct. 2020, doi: 10.1002/fld.4928.

H. Boudounit, M. Tarfaoui, and D. Saifaoui, “Fatigue analysis of wind turbine composite blade using finite element method,” Wind Engineering, vol. 47, no. 3, pp. 706–721, Feb. 2023, doi: 10.1177/0309524x231155549.

F. Ruggiero et al., “Finite element method for the design of implants for temporal hollowing,” JPRAS Open, vol. 32, pp. 18–23, Jun. 2022, doi: 10.1016/j.jpra.2021.12.001.

E. Demir, G. Yalçın, A. Kalaycı, and H. Sağlam, “Biomechanical evaluation of caudally and buccally screwed customised reconstruction plates for lateral segmental defects of mandible,” British Journal of Oral and Maxillofacial Surgery, vol. 59, no. 8, pp. 928–934, Oct. 2021, doi: 10.1016/j.bjoms.2020.10.017.

T. Bagherpoor and L. Xuemin, “Structural Optimization Design of 2MW Composite Wind Turbine Blade,” Energy Procedia, vol. 105, pp. 1226–1233, May 2017, doi: 10.1016/j.egypro.2017.03.420.

R. Kadge, “Finite Element Analysis on Design Optimized Bevel Gear Pair to Check Its Durability,” SAE International Journal of Passenger Vehicle Systems, vol. 15, no. 1, Mar. 2022, doi: 10.4271/15-15-01-0005.

Z. Zhang et al., “Space deployable bistable composite structures with C-cross section based on machine learning and multi-objective optimization,” Composite Structures, vol. 297, p. 115983, Oct. 2022, doi: 10.1016/j.compstruct.2022.115983.

M. Ben Jaber, H. Smaoui, and P. Terriault, “Finite element analysis of a shape memory alloy three-dimensional beam based on a finite strain description,” Smart Materials and Structures, vol. 17, no. 4, p. 045005, May 2008, doi: 10.1088/0964-1726/17/4/045005.

T. Long, C. Huang, D. Hu, and M. Liu, “Coupling edge-based smoothed finite element method with smoothed particle hydrodynamics for fluid structure interaction problems,” Ocean Engineering, vol. 225, p. 108772, Apr. 2021, doi: 10.1016/j.oceaneng.2021.108772.

C. R. Vindigni, G. Mantegna, A. Esposito, C. Orlando, and A. Alaimo, “An aeroelastic beam finite element for time domain preliminary aeroelastic analysis,” Mechanics of Advanced Materials and Structures, vol. 30, no. 5, pp. 1064–1072, Sep. 2022, doi: 10.1080/15376494.2022.2124333.

D. D. Angela and M. Ercolino, “Finite Element Analysis of Fatigue Response of Nickel Steel Compact Tension Samples using ABAQUS,” Procedia Structural Integrity, vol. 13, pp. 939–946, 2018, doi: 10.1016/j.prostr.2018.12.176.

S. E. F. Huys, A. Van Gysel, M. Y. Mommaerts, and J. V. Sloten, “Evaluation of Patient-Specific Cranial Implant Design Using Finite Element Analysis,” World Neurosurgery, vol. 148, pp. 198–204, Apr. 2021, doi: 10.1016/j.wneu.2021.01.102.

P. Ruf et al., “Towards mechanobiologically optimized mandible reconstruction: CAD/CAM miniplates vs. reconstruction plates for fibula free flap fixation: A finite element study,” Frontiers in Bioengineering and Biotechnology, vol. 10, Nov. 2022, doi: 10.3389/fbioe.2022.1005022.

A. S. Escalera Mendoza, S. Yao, M. Chetan, and D. T. Griffith, “Design and analysis of a segmented blade for a 50 MW wind turbine rotor,” Wind Engineering, vol. 46, no. 4, pp. 1146–1172, Jan. 2022, doi: 10.1177/0309524x211069393.

K. Aggarwal, S. Wu, and J. Papangelis, “Finite element analysis of local shear buckling in corrugated web beams,” Engineering Structures, vol. 162, pp. 37–50, May 2018, doi: 10.1016/j.engstruct.2018.01.016.

A. Borgia et al., “Swept-Source Optical Coherence Tomography-Based Biometry: A Comprehensive Overview,” Photonics, vol. 9, no. 12, p. 951, Dec. 2022, doi: 10.3390/photonics9120951.

P. Bortolotti, N. Johnson, N. J. Abbas, E. Anderson, E. Camarena, and J. Paquette, “Land-based wind turbines with flexible rail-transportable blades – Part 1: Conceptual design and aeroservoelastic performance,” Wind Energy Science, vol. 6, no. 5, pp. 1277–1290, Sep. 2021, doi: 10.5194/wes-6-1277-2021.

E. Fatehi, H. Yazdani Sarvestani, B. Ashrafi, and A. H. Akbarzadeh, “Accelerated design of architectured ceramics with tunable thermal resistance via a hybrid machine learning and finite element approach,” Materials & Design, vol. 210, p. 110056, Nov. 2021, doi: 10.1016/j.matdes.2021.110056.

G. P. Serafeim, D. I. Manolas, V. A. Riziotis, P. K. Chaviaropoulos, and D. A. Saravanos, “Optimized blade mass reduction of a 10MW-scale wind turbine via combined application of passive control techniques based on flap-edge and bend-twist coupling effects,” Journal of Wind Engineering and Industrial Aerodynamics, vol. 225, p. 105002, Jun. 2022, doi: 10.1016/j.jweia.2022.105002.

F. P. Moncayo-Matute et al., “Surgical planning and finite element analysis for the neurocraneal protection in cranioplasty with PMMA: A case study,” Heliyon, vol. 8, no. 9, p. e10706, Sep. 2022, doi: 10.1016/j.heliyon. 2022.e10706.

X. Wang and B. Song, “Application of bionic design inspired by bamboo structures in collapse resistance of thin-walled cylindrical shell steel tower,” Thin-Walled Structures, vol. 171, p. 108666, Feb. 2022, doi: 10.1016/j.tws.2021.108666.

B. J. Shelp, E. J. Flaherty, W. J. Sutton, L. M. Schenck, and J. Aalbers, “Commercial validation of a modified method for delivering low nitrogen, phosphorus, and potassium inputs to greenhouse-grown subirrigated pot chrysanthemums,” Canadian Journal of Plant Science, vol. 101, no. 6, pp. 962–966, Dec. 2021, doi: 10.1139/cjps-2020-0294.

M. Hussain et al., “Recent Developments in Coatings for Orthopedic Metallic Implants,” Coatings, vol. 11, no. 7, p. 791, Jun. 2021, doi: 10.3390/coatings11070791.

J. Ke and Y. Yoshikuni, “Multi-chassis engineering for heterologous production of microbial natural products,” Current Opinion in Biotechnology, vol. 62, pp. 88–97, Apr. 2020, doi: 10.1016/j.copbio.2019.09.005.

J. Jacob and S. Bozkurt, “Automated surgical planning in spring-assisted sagittal craniosynostosis correction using finite element analysis and machine learning,” PLOS ONE, vol. 18, no. 11, p. e0294879, Nov. 2023, doi: 10.1371/journal.pone.0294879.

R. K. Et. al., “Finite Element Analysis of Honeycomb Sandwich Composite Structures With Various Joints,” Turkish Journal of Computer and Mathematics Education (TURCOMAT), vol. 12, no. 1S, pp. 531–535, Apr. 2021, doi: 10.17762/turcomat.v12i1s.1922.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2024 Khaled Kamal Oude, Ali Adelkhani

This work is licensed under a Creative Commons Attribution 4.0 International License.