Experimental Study of Two Rows Hybrid Film Cooling Holes Over Flat Plate Surface Using IR Technology

DOI:

https://doi.org/10.51173/jt.v5i3.1231Keywords:

Film Cooling, Cylindrical Holes, Hybrid Holes, Infrared Technology, Film Cooling EffectivenessAbstract

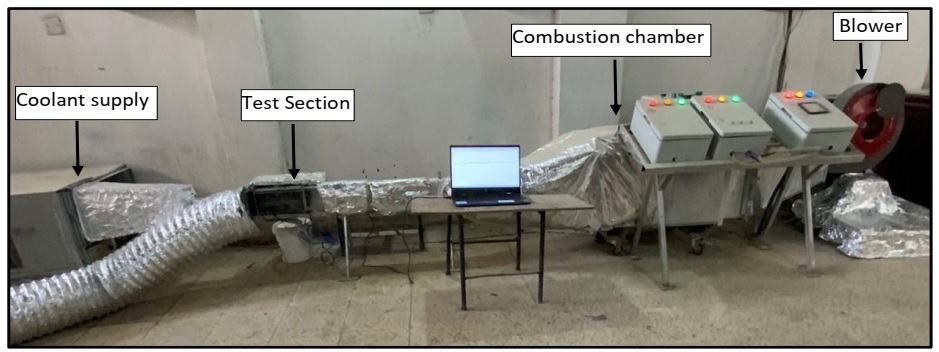

The study examines the effectiveness of two rows of hybrid film cooling holes over a plate surface using infrared technology and a thermal wind tunnel. The two rows consist of seventeen coolant injection holes, with nine in the first row and eight in the second row. Two cases were studied: case 1 using cylindrical holes and case 2 using hybrid holes. Both cases had the same cross-sectional area with a hydraulic diameter of 5.3 mm and a forward coolant injection angle of 30° in the streamwise direction. Different blowing ratios (mass flows ratio between the coolant and mainstream) were tested at 0.5, 1.0, and 1.5. The study focuses on evaluating the impact of hole shape with various blowing ratios on film cooling effectiveness. In addition, thermal images of the test surface were taken via an infrared camera after reaching a steady state. The results indicated that at a blowing ratio of 0.5, there was a significant enhancement in film efficacy, with a decrease in the test surface temperature of the cylinder and hybrid hole cases by 31.8% and 35.0%, respectively, when compared to a blowing ratio of 1.0 and 1.5, which had a temperature increase. Therefore, the film cooling effectiveness decreased to 30.9% and 32.4%, and 29.5% and 31.7% for the cylinder and hybrid hole cases, respectively. Additionally, the better overall film cooling effectiveness in this study was achieved by the configuration of the hybrid holes at a blowing ratio of 0.5, which resulted in a film cooling effectiveness of 35.0%

Downloads

References

J. C. Han, “Fundamental gas turbine heat transfer,” J. Therm.Sci. Eng. Appl., vol. 5, no. 2, May. 2013.

J. C. Han, S. Dutta, and S. Ekkad, “Gas Turbine Heat Transfer and Cooling Technology”. Taylor & Francis Group., 2012.

R. J. Goldstein, S. Ito, and E. R. G. Eckert, “Film cooling of a gas turbine blade,” J. Eng. Gas Turbines Power, vol. 100, no. 3, pp. 476–481, 1978.

R. J. Goldstein and M. Y. Jabbari, “Adiabatic Wall Temperature and Heat Transfer Downstream of Injection Through Two Rows of Holes,” vol. 100, no. April 1978, pp. 303–307, 2017.

M. G. Ghorab and I. G. Hassan, “International Journal of Heat and Mass Transfer An experimental investigation of a new hybrid film cooling scheme,” Int. J. Heat Mass Transf., vol. 53, no. 21–22, pp. 4994–5007, 2010.

M. A. H. Abdelmohimen, I. Anjum, B. C. Ahamed, and S. T. M. Yunus, “Numerical Analysis of Film Cooling Due to Simple / Compound Angle Hole Combination,” Arab. J. Sci. Eng., 2020.

Z. Shu, C. Dai, and J. Mi, “Numerical simulations on film cooling effectiveness from two staggered rows of coolant jets,” Lect. Notes Mech. Eng., no. 1991, pp. 143–148, 2019.

H. A. Daud and M. F. Mohammed, “Film Cooling Holes Performance on a Flat Plate,” J. Mech. Eng., vol. 19(3), pp. 73–91, 2022.

K. Singh, B. Premachandran, and M. R. Ravi, “Experimental assessment of film cooling performance of short cylindrical holes on a flat surface,” Int. J. Heat Mass Transf., vol. 52, no. 12, pp. 2849–2862, 2016.

K. Kusterer, D. Bohn, T. Sugimoto, and R.Tanaka, “Double-jet Ejection of Cooling Air for Improved Film Cooling,” ASME j, 2006.

A. A. Naji, H. A. Daud and N. J. Yasin “Assessment of coolant jet over flat plate surface with two staggered rows of holes by using infrared technology,” 4th International Conference on Sustainable Engineering Techniques, October 2022.

M. Kunze, K. Vogeler, G. Brown, C. Prakash, and K. Landis, “Aerodynamic and Endwall Film-Cooling Investigations of a Gas Turbine Nozzle Guide Vane Applying Temperature-Sensitive Paint,” J. Turbomachinery, vol. 133, no. 3, Feb. 2011.

A. Lerch, R. Bauer, J. Krueckels, and M. Henze, “Impact of a Combustor–Turbine Interface on Turbine Vane Aerodynamics and Film Cooling,” J. Turbomachinery., vol. 142, no. 7, 2020.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Ahmed A. Naji, Harbi A. Daud, Nabil J. Yasin, Ahmed A. Jasim

This work is licensed under a Creative Commons Attribution 4.0 International License.