Investigation of Using the IL-FSSW Technique to Weld AA5052-H112 Alloy with Copper: Experimental Study

DOI:

https://doi.org/10.51173/jt.v5i4.1950Keywords:

Aluminum Alloys, Pure Copper, Friction Stir Spot Welding, Keyhole Problem, IL-FSSWAbstract

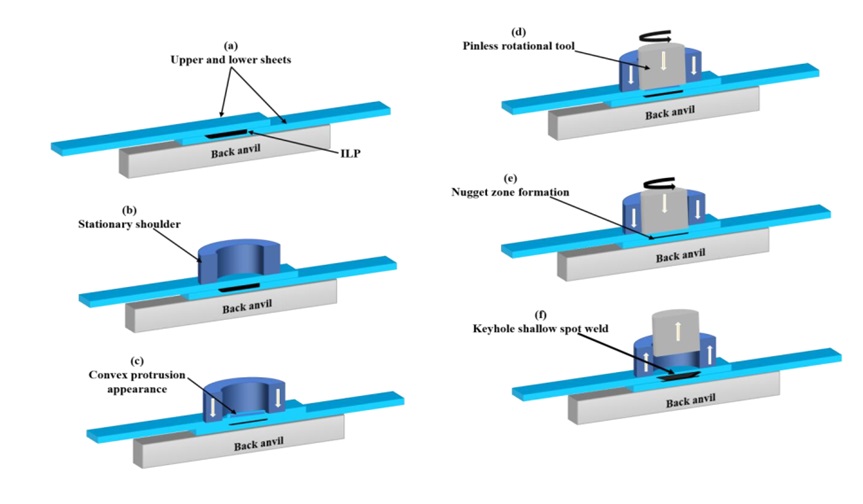

In this research, a developed welding technique (IL-FSSW) was used to bond alloys from Aluminum with pure Copper. Aluminium alloy AA5052-H112 and pure copper with an intermediate layer from the same base metal with a thickness of 2mm were used in the present study. The mechanism of achieving spot welding in this process differed from that of the conventional FSSW process in terms of introducing the Intermediate layer (IL) and using a pinless tool to solve the keyhole problem, and get a flat surface for the welding spot, thus increasing the tensile shear strength of the joints which makes it suitable for engineering applications. In addition, the work is based on the use of solid-state welding to eliminate the problems of conventional fusion welding methods, and this reduces the additional operations or subsequent treatments of welding and makes them unnecessary. The work was evaluated by examining the tensile shear strength and analysing the microstructure using light microscopy. The results showed a good joint appearance with shallow keyholes. The failure load value from the shear tensile test was 5008 N, obtained at a Rotating speed of 1400 rpm, feeding 20 mm/min, soaking time 20 sec, and preheating 20 sec, which was higher after comparing with the required strength value by the requirements of the American Welding Society. The microstructure images of the cross-section of the sample showed a change in the size of the crystalline grains between the welded zone and the base metal.

Downloads

References

W. Zhang, Y. Shen, Y. Yan, R. Guo, W. Guan, and G. Guo, "Microstructure characterization and mechanical behavior of dissimilar friction stir welded Al/Cu couple with different joint configurations," The International Journal of Advanced Manufacturing Technology, vol. 94, pp. 1021-1030, 2018, DOI 10.1007/s00170-017-0961-2.

C. Zhang and A. A. Shirzadi, "Measurement of residual stresses in dissimilar friction stir-welded aluminum and Copperplates using the contour method," Science and Technology of Welding and Joining, vol. 23, no. 5, pp. 394-399, 2018. DOI.org/10.1080/13621718.2017.1402846.

W. Miller et al., "Recent development in aluminum alloys for the automotive industry," Materials Science and Engineering: A, vol. 280, no. 1, pp. 37-49, 2000, DOI.org/10.1016/S0921-5093(99)00653-X

I. T. Abdullah, "Friction Spot Joining of Aluminium Alloy AA 5052 To Pre-Holed Steel AISI 1006 By Extrusion Aluminium Into A Rivet Head Die," Journal of Techniques, vol. 4, no. 2, pp. 10-20, 2022, DOI.org/10.51173/jt.v4i2.492.

S. N. A. Wahed, S. K. Hussein, and M. H. Al-Saadi, "Disc Forming by Friction Stir Consolidation of AA2024 Chips," Journal of Techniques, vol. 4, no. 1, pp. 1-8, 2022, DOI.org/10.51173/jt.v4i1.442.

P. Sahlot, A. K. Singh, V. J. Badheka, and A. Arora, "Friction stir welding of copper: numerical modeling and validation," Transactions of the Indian Institute of Metals, vol. 72, pp. 1339-1347, 2019, DOI.org/10.1007/s12666-019-01629-9.

A. Heidarzadeh, H. M. Laleh, H. Gerami, P. Hosseinpour, M. J. Shabestari, and R. Bahari, "The origin of different microstructural and strengthening mechanisms of Copper and brass in their dissimilar friction stir welded joint," Materials Science and Engineering: A, vol. 735, pp. 336-342, 2018, DOI.org/10.1016/j.msea.2018.08.068.

J. Ouyang, E. Yarrapareddy, and R. Kovacevic, "Microstructural evolution in the friction stir welded 6061 Aluminum alloy (T6-temper condition) to copper," Journal of materials processing technology, vol. 172, no. 1, pp. 110-122, 2006, DOI.org/10.1016/j.jmatprotec.2005.09.013.

W.-B. Lee and S.-B. Jung, "Void free friction stir weld zone of the dissimilar 6061 Aluminum and Copperjoint by shifting the tool insertion location," Materials research innovations, vol. 8, no. 2, pp. 93-96, 2004, DOI.org/10.1080/14328917.2004.11784837.

M. Li, C. Zhang, D. Wang, L. Zhou, D. Wellmann, and Y. Tian, "Friction stir spot welding of Aluminum and copper: a review," Materials, vol. 13, no. 1, p. 156, 2019, DOI:10.3390/ma13010156.

A. Lakshminarayanan, M. Suresh, and M. Sibi Varshan, "Thermal performance evaluation of friction stir welded and bolted cold plates with Al/Cu interface," JOM, vol. 67, pp. 1032-1044, 2015, DOI: 10.1007/s11837-015-1393-9.

H. Bisadi, A. Tavakoli, M. T. Sangsaraki, and K. T. Sangsaraki, "The influences of rotational and welding speeds on microstructures and mechanical properties of friction stir welded Al5083 and commercially pure Coppersheets lap joints," Materials & Design, vol. 43, pp. 80-88, 2013, DOI.org/10.1016/j.matdes.2012.06.029.

G. Li, L. Zhou, W. Zhou, X. Song, and Y. Huang, "Influence of dwell time on microstructure evolution and mechanical properties of dissimilar friction stir spot welded Aluminum–Coppermetals," Journal of Materials Research and Technology, vol. 8, no. 3, pp. 2613-2624, 2019, DOI.org/10.1016/j.jmrt.2019.02.015.

L. Zhou et al., "Microstructure evolution and mechanical properties of friction stir spot welded dissimilar Aluminum-Copperjoint," Journal of Alloys and Compounds, vol. 775, pp. 372-382, 2019, DOI.org/10.1016/j.jallcom.2018.10.045.

M. Acarer, "Electrical, corrosion, and mechanical properties of Aluminum-Copperjoints produced by explosive welding," Journal of Materials Engineering and Performance, vol. 21, no. 11, pp. 2375-2379, 2012, DOI: 10.1007/s11665-012-0203-6.

T. Iwashita, "Method and apparatus for joining," ed: Google Patents, 2003.

D. Mitlin, V. Radmilovic, T. Pan, J. Chen, Z. Feng, and M. Santella, "Structure–properties relations in spot friction welded (also known as friction stir spot welded) 6111 Aluminum," Materials Science and Engineering: A, vol. 441, no. 1-2, pp. 79-96, 2006, DOI.org/10.1016/j.msea.2006.06.126.

M. P. Mubiayi and E. T. Akinlabi, "Evolving properties of friction stir spot welds between AA1060 and commercially pure CopperC11000," Transactions of Nonferrous Metals Society of China, vol. 26, no. 7, pp. 1852-1862, 2016, DOI.org/10.1016/S1003-6326(16)64296-6.

A. Garg and A. Bhattacharya, "Strength and failure analysis of similar and dissimilar friction stir spot welds: Influence of different tools and pin geometries," Materials & Design, vol. 127, pp. 272-286, 2017, DOI.org/10.1016/j.matdes.2017.04.084.

A. N. Colmenero et al., "Optimization of friction stir spot welding process parameters for Al-Cu dissimilar joints using the energy of the vibration signals," The International Journal of Advanced Manufacturing Technology, vol. 100, pp. 2795-2802, 2019, DOI.org/10.1007/s00170-018-2779-y.

I. J. Ibrahim and G. G. Yapici, "Optimization of the intermediate layer friction stir spot welding process," The International Journal of Advanced Manufacturing Technology, vol. 104, pp. 993-1004, 2019, DOI.org/10.1007/s00170-019-03952-3.

J. R. Davis, "Metals handbook desk edition," (No Title), 1998.

A. Society, "Specification for resistance welding for aerospace applications," ed: American Welding Society, 2013, DOI.org/10.1007/s00170-018-2609-2.

A. W. Society, A. W. S. C. o. M. T. o. Welds, and A. W. S. T. A. Committee, Standard methods for mechanical testing of welds. American Welding Society, 2007.

S. Hedrick, A. Alonso, and D. Hernandez, "American Welding Society," Australasian Welding Journal, vol. 58, pp. 16-17, 2013.

L. Zhou, R. Zhang, G. Li, W. Zhou, Y. Huang, and X. Song, "Effect of pin profile on microstructure and mechanical properties of friction stir spot welded Al-Cu dissimilar metals," Journal of Manufacturing Processes, vol. 36, pp. 1-9, 2018, DOI.org/10.1016/j.jmapro.2018.09.017.

S. Siddharth and T. Senthilkumar, "Study of tool penetration behavior in dissimilar Al5083/C10100 friction stir spot welds," Procedia Engineering, vol. 173, pp. 1439-1446, 2017, DOI: 10.1016/j.proeng.2016.12.209.

R. Heideman, C. Johnson, and S. Kou, "Metallurgical analysis of Al/Cu friction stir spot welding," Science and Technology of Welding and Joining, vol. 15, no. 7, pp. 597-604, 2010, DOI.org/10.1179/136217110X12785889549985.

Y. Zuo, L. Kong, Z. Liu, Z. Lv, and H. Wen, "Process parameters optimization of refill friction stir spot welded Al/Cu joint by response surface method," Transactions of the Indian Institute of Metals, vol. 73, pp. 2975-2984, 2020, DOI.org/10.1007/s12666-020-02100-w.

S. Manickam, C. Rajendran, and V. Balasubramanian, "Investigation of FSSW parameters on shear fracture load of AA6061 and Copper alloy joints," Heliyon, vol. 6, no. 6, p. e04077, 2020, DOI.org/10.1016/j.heliyon.2020.e04077.

Y. Zuo, P. Gong, S. Ji, Q. Li, Z. Ma, and Z. Lv, "Ultrasound-assisted friction stir transient liquid phase spot welded dissimilar copper-Aluminum joint," Journal of Manufacturing Processes, vol. 62, pp. 58-66, 2021, DOI.org/10.1016/j.jmapro.2020.11.019.-

M. K. Abbass, S. K. Hussein, and A. A. Kudair, "Optimization and Characterization of Friction Stir Spot Welding of Aluminum Alloy (AA 5754-H114) with Pure CopperSheet," in IOP Conference Series: Materials Science and Engineering, 2021, vol. 1094, no. 1: IOP Publishing, p. 012054, DOI 10.1088/1757-899X/1094/1/012054.

H. Liu, Y. Zuo, S. Ji, J. Dong, and H. Zhao, "Friction stir solid–liquid spot welding of Cu to Al assisted by Zn interlayer," Journal of Materials Research and Technology, vol. 18, pp. 85-95, 2022, DOI.org/10.1016/j.jmrt.2022.02.067.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Kareem Abbas Falih, Isam Jabbar Ibrahim, Sabah Khammass Hussein, Salah Mezlini

This work is licensed under a Creative Commons Attribution 4.0 International License.