Mechanical Behaviour of Polymer Matrix Composite Reinforced by Silicon Carbide Particles

DOI:

https://doi.org/10.51173/jt.v5i2.949Keywords:

Epoxy, Silicon Carbide, Composites, Impact Strength, Tensile StrengthAbstract

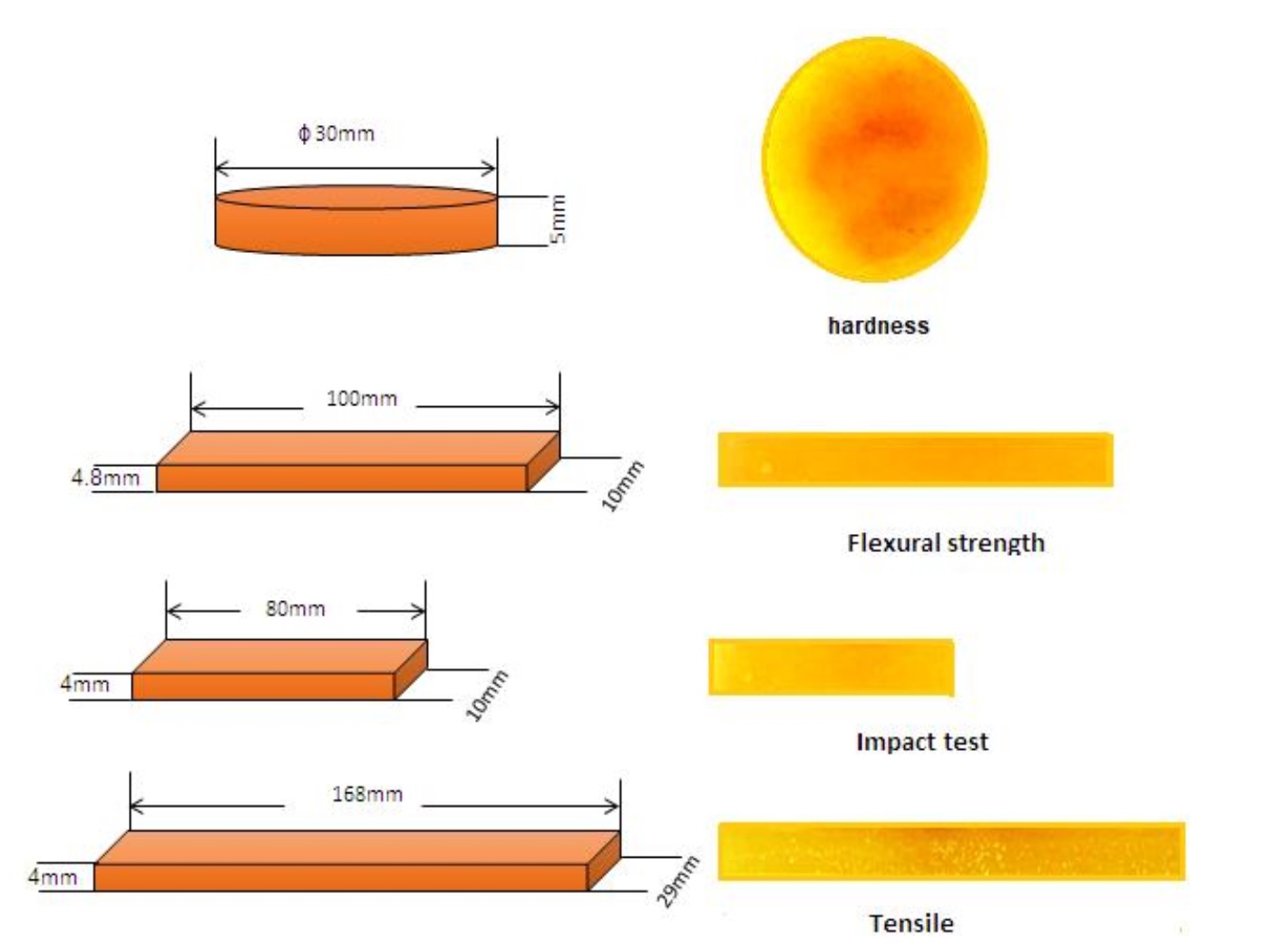

In various fields, Polymer-based composites are used extensively instead of traditional materials. The hand lay-up technology has been employed to prepare the composites of Silicon carbide particles-epoxy. Mechanical properties; shore D hardness, Flexural strength, tensile strength and impact strength were measured for all specimens. The present work has also studied the impact of different weight percentages (including 3, 6, 9, 12, 15 and 18) wt.% of SiC solid powder on the mechanical properties of fabricated samples with two average particle sizes of 75 and 105 µm. SiC particles were utilized as reinforcement with the epoxy with hardener according to the mixing of (3:1) ratio. The experimental results found that hardness, flexural strength and impact strength can be increased by increasing the weight percentage of Silicon carbide, while tensile strength is decreased with an increased weight fraction of silicon carbide. At the same time, these properties were enhanced when the particles of SiC have 75 µm more than at 105 µm.

Downloads

References

Devendra, K., & Rangaswamy, T., “Strength Characterization of E-glass fiber Reinforced Epoxy Composites with Filler Materials,” Journal of Minerals and Materials Characterization and Engineering, vol. 01, issue 06, 2013.

Abbas RA, “Studying Some Dielectric Properties and Effective Parameters of Composite Materials Containing of Novolak Resin,” Journal of Engineering and Technology vol. 25, pp. 277-288, 2007.

Zhou, W., Yu, D., Min, C., Fu, Y., Guo, X., “Thermal, dielectric, and mechanical properties of SiC particles filled linear low-density polyethene composites,” J. Appl. Polym. Sci., vol.112, pp. 1695–1703, 2009.

Jin, F.L., Zhang, H., Yao, S.S., Park, S.J., “Effect of surface modification on impact strength and flexural strength of poly (Lactic acid)/silicon carbide nanocomposites,” Macromol. Res., vol. 26, pp. 211–214, 2018.

Miracle D. B., Donaldson S. L. Introduction to composites. In Composites, (Eds Miracle D. B., Donaldson S. L.), vol. 21, 2001, pp. 3–17 (ASM Handbook, ASM, Material Park, Ohio, USA), 2001, pp. 1089–1093.

Madhusudhan T, Senthi L and Kumar M., “Comparison of hybrid composites with different filler material,” Int J Eng Res Gen Sci, vol. 4, issue196, 2016.

Antunes PV, Ramalho A, Carrilho EV P., Mater. Des., vol. 61, pp. 50-60, 2014.

N.G. Chanshetti, and A.S. Pol, “Wear behaviour of TiO2 and WC reinforced epoxy resin composites,” Int. Res. J. Eng. Technol, vol. 3, pp. 2395-0056, 2016.

Shohel Rana1, Mahbub Hasan2, Md Rezaul Karim Sheikh1 and A Nayeem Faruqui1, “Effects of aluminium and silicon carbide on morphological and mechanical properties of epoxy hybrid composites,” Polymers and Polymer Composites, vol. 30, pp.1–9, 2022.

Aleksandra Jeli´c, Milica Sekuli´c , Milan Travica , Jelena Gržeti´c , Vukašin Ugrinovi´c , Aleksandar D. Marinkovi´c , Aleksandra Boži´c, Marina Stamenovi´c and Slaviša Puti´c , “Determination of Mechanical Properties of Epoxy Composite Materials Reinforced with Silicate Nanofillers Using Digital Image Correlation (DIC)”, Polymers 2022, 14, 1255.

T. Madhusudan and K. Senthil, “Mechanical characterization of jute and rubber particles reinforced epoxy polymer composites,” IOSR Journal of Pharmacy, vol. 6, issue.12, pp. 23-27, 2016.

M. Chary and K. S. Ahmed, “Experimental characterization of coconut shell particle reinforced epoxy composites,” Journal of Materials and Environmental Sciences”, vol. 8, issue .5, pp. 1661-1667, 2017.

G.U. Raju and S. Kumarappa, “Experimental study on mechanical properties of Peanut shell particle reinforced epoxy composites,” Journal of Reinforced Plastics and Composites, vol. 30, issue.12, pp.1029–1037, 2015.

Annual Book of ISO- 180. Standard, “Standard test methods for unnotched izod impact testing of plastics,” ISO-180, PP.1-2, 2006.

Annual Book of ASTM Standard, "Standard test methods for flexural properties of unreinforced and reinforced plastics D 790- 86,” Vol. 10.01, 1986.

Standard Test Method for Rubber property Durometer Hardness. ASTM International November 2017, p.5.

Annual Book of ASTM, Section 8, Vol.08.01 Plastic, "Am.Soc. Test Mat." Philadelphia, (2004).

Hazim Faleh Hassan, Muna Noori Ismae and Suroor Noori Ismail, “Effect of metal powder Nickel, Iron and Aluminium on Mechanical and Electrical Properties of Epoxy Composites,” ICEST 2020, IOP Conf. Series: Materials Science and Engineering 1090 (2021) 012086.

Jabbar Hussein Mohmmed, “Evaluation the Mechanical Properties of Kaolin Particulate Reinforced Epoxy Composites,” Al-Khwarizmi Engineering Journal, vol.14, issue 1, pp. 29-38, 2018.

N. J. Saleh, and S. N. Mustafa, " A Study of Some Mechanical, Thermal and Physical Properties of Polymer Blend with Iraqi Kaolin Filler," Eng. and Tech. Journal, vol. 29, issue 11, pp. 2114-2131, 2011.

Dr. Ibtihal-Al-Namie, Dr Ahmed Aladdin Ibrahim, Manal Fleyah Hassan, “Study the Mechanical Properties of Epoxy Resin Reinforced With silica (quartz) and Alumina Particle,” The Iraqi Journal for Mechanical and Material Engineering, vol.11,issue 3, 2011.

Yelda Akcin Ergun, “Mechanical properties of Epoxy Composite Materials Produced with Different Ceramic Powders,” Journal of Materials Science and Chemical Engineering, vol.7, issue 12, December 2019.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Muna Noori Ismael, Hazim F. Hassan

This work is licensed under a Creative Commons Attribution 4.0 International License.