An Investigation of Joining Polyamide (PA) to Stainless Steel AISI 316L by Hot Press Process

DOI:

https://doi.org/10.51173/jt.v5i1.1280Keywords:

Hot Press Process, Polyamide, AISI 316LAbstract

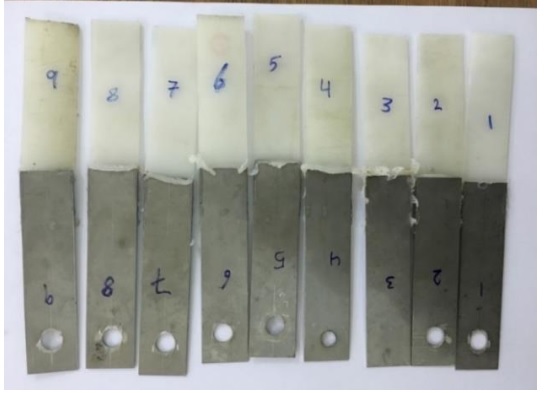

A hot press process was used as a technique to pound a polyamide type of polymer of a thickness (2mm) to stainless steel AISI 316L of the thickness (1mm). A hybrid joint of dissimilar material was accomplished by a hot press bonding process. During the joining process, three different parameters of process were used: processing temperature of 175, 170 and 165°C, processing pressure of 3, 6 and 9 bar and time of 1.5, 3 and 4.5 min. The surface of stainless steel was prepared and treated by a mechanical treatment (surface grinding) to improve the wettability to increase the shear strength. A shear tensile, scanning electron microscope (SEM) and energy dispersive spectrometry (EDS) tests were used to investigate and examine the joint (bounding) specimens. The Minitab program was used to analyze the effect of the parameters of the joining process on the joint properties. The maximum and minimum values of shear force are exhibited at a processing temperature of 165°C, applied pressure of 6 bars and processing time of 1.5 minutes; the minimum shear force was found to be 675 N, while the maximum shear force was 2182 N at a processing temperature of 175°C, applied pressure of 6 bars and processing time of 3 minutes. The tested joints failed by an interfacial shear and necking in the polymer side with a ductile fracture. The joining process occurred through a mechanical interlocking between the molten polymer and the treated surface of the steel specimen. The average thickness of the joining line for the tested specimens was 8µm.

Downloads

References

Kadiyala, A. K., & Bijwe, J. (2018). Poly (ether ether ketone)-Silicon carbide composite adhesives for elevated temperature applications of stainless steel joints. Composites Science and technology, 155, 177-188, https://doi.org/10.1016/j.compscitech.2017.12.004.

Wang, H., Yang, K., & Liu, L. (2018). The analysis of welding and riveting hybrid bonding joint of aluminum alloy and polyether-ether-ketone composites. Journal of Manufacturing Processes, 36, 301-308, https://doi.org/10.1016/j.jmapro.2018.10.031.

Huang, Y., Meng, X., Xie, Y., Li, J., & Wan, L. (2019). New technique of friction-based filling stacking joining for metal and polymer. Composites Part B: Engineering, 163, 217-223, https://doi.org/10.1016/j.compositesb.2018.11.050.

Bragança, I. M. F., Silva, C. M. A., Alves, L. M., & Martins, P. A. F. (2017). Lightweight joining of polymer and polymer-metal sheets by sheet-bulk forming. Journal of Cleaner Production, 145, 98-104, https://doi.org/10.1016/j.jclepro.2017.01.049.

Hamzah, M. M., & Hussein, S. K. (2020, February). Effect of Surface Pretreatment on Hot Press Lap joining of High Density Polyethylene to Stainless Steel Alloy AISI 304L. In IOP Conference Series: Mterials Science and Engineering (Vol. 745, No. 1, p. 012058). IOP Publishing, https://doi.org/10.1088/1757-899X/745/1/012058 .

Jiao, J., Xu, Z., Wang, Q., Sheng, L., & Zhang, W. (2018). CFRTP and stainless steel laser joining: Thermal defects analysis and joining parameters optimization. Optics & Laser Technology, 103, 170-176, https://doi.org/10.1016/j.optlastec.2018.01.023.

Huang, Y., Meng, X., Xie, Y., Li, J., & Wan, L. (2018). Joining of carbon fiber reinforced thermoplastic and metal via friction stir welding with co-controlling shape and performance. Composites Part A: Applied Science and Manufacturing, 112, 328-336, https://doi.org/10.1016/j.compositesa.2018.06.027.

Amancio‐Filho, S. T., & Dos Santos, J. F. (2009). Joining of polymers and polymer–metal hybrid structures: recent developments and trends. Polymer engineering & science, 49(8), 1461-1476, https://doi.org/10.1002/pen.21424

Kah, P., Suoranta, R., Martikainen, J., & Magnus, C. (2014). Techniques For Joining Dissimilar Materials: Metals And Polymers. Reviews on Advanced Materials Science, 36(2).

Lamberti, C., Solchenbach, T., Plapper, P., & Possart, W. (2014). Laser assisted joining of hybrid polyamide-aluminum structures. Physics Procedia, 56, 845-853, https://doi.org/10.1016/j.phpro.2014.08.103.

Kajihara, Y., Tamura, Y., Kimura, F., Suzuki, G., Nakura, N., & Yamaguchi, E. (2018). Joining strength dependence on molding conditions and surface textures in blast-assisted metal-polymer direct joining. CIRP Annals, 67(1), 591-594, https://doi.org/10.1016/j.cirp.2018.04.112.

Arkhurst, B. M., Kim, J. H., & Lee, M. Y. (2019). Hot metal pressing joining of carbon fiber reinforced plastic to AZ31 Mg alloy and the effect of the oxide surface layer on joint strength. Applied Surface Science, 477, 241-256, https://doi.org/10.1016/j.apsusc.2017.10.009.

Balle, F., Wagner, G., & Eifler, D. (2007). Ultrasonic spot welding of aluminum sheet/carbon fiber reinforced polymer–joints. Materialwissenschaft und Werkstofftechnik: Entwicklung, Fertigung, Prüfung, Eigenschaften und Anwendungen Technischer Werkstoffe, 38(11), 934-938, https://doi.org/10.1002/mawe.200700212

Katayama, S., & Kawahito, Y. (2008). Laser direct joining of metal and plastic. Scripta materialia, 59(12), 1247-1250, https://doi.org/10.1016/j.scriptamat.2008.08.026.

Abdullah, I. T. (2022). Friction Spot Joining of Aluminium Alloy AA 5052 To Pre-Holed Steel AISI 1006 By Extrusion Aluminium Into A Rivet Head Die. Journal of Techniques, 4(2), 10-20, https://doi.org/10.51173/jt.v4i2.492 .

Barrak, O. S., Saad, M. L., Mezher, M. T., Hussein, S. K., & Hamzah, M. M. (2020, July). Joining of double pre-holed aluminum alloy AA6061-T6 to polyamide PA using hot press technique. In IOP Conference Series: Materials Science and Engineering (Vol. 881, No. 1, p. 012062). IOP Publishing, https://doi.org/10.1088/1757-899X/881/1/012062 .

American Society for Metals (ASM), “Properties and Selection: Irons, Steels, and High Performance Alloys”, ASM Handbook, Volume 1, 01 Sep. 2005.

ANSI/AWS C1.1M/C1.1:2012, “Recommended Practices for Resistance Welding”, American Welding Society.

Hart-Smith, L. J. (1999). A peel-type durability test coupon to assess interfaces in bonded, co-bonded, and co-cured composite structures. International journal of adhesion and adhesives, 19(2-3), 181-191, https://doi.org/10.1016/S0143-7496(98)00033-5.

Ratanathavorn, W. (2012). Hybrid joining of aluminium to thermoplastics with friction stir welding (FSW).

M.S. thesis, Department of Materials Science and Engineering, KTH-Royal Institute of Technology, Stockholm, Sweden, 2012.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Osamah Sabah Barrak, Osamah Fattah Taresh, Mahmood Mohammed Hamzah, Rusul Ahmed Shakir

This work is licensed under a Creative Commons Attribution 4.0 International License.