Joining of Polymer to Aluminum Alloy AA1050 By Friction Spot Welding

DOI:

https://doi.org/10.51173/jt.v5i4.1976Keywords:

Friction Spot Welding (FSW), Polymer, AA1050Abstract

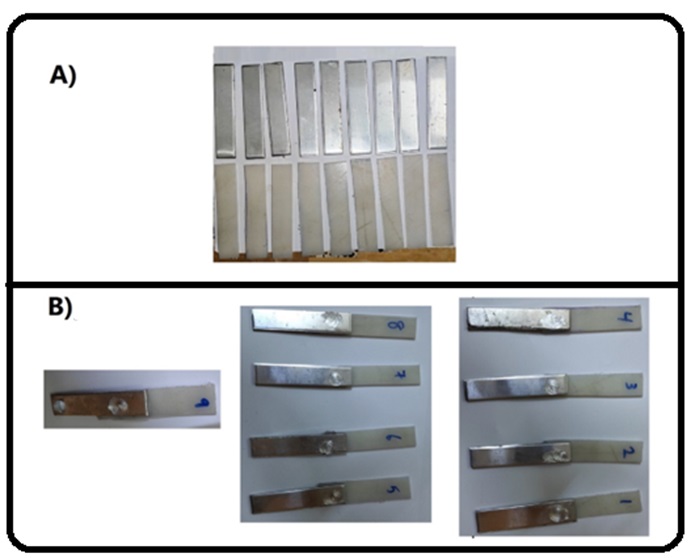

The friction spot welding process is used to join the hybrid joint of aluminium to polymer. AA 1050 Aluminum alloy and polyethylene polymer (type of plastic) were used for joining. Aluminium surface treatment was done to increase the wettability of it. The surface treatment was done by electrochemical treatment. Two parameters of the joining process were used: (1, 1.5 and 2) min. (920, 1340 and 1500) rpm for time and rotational speed, respectively. Many tests for the joint are done: shear test and Scanning electron microscopy (SEM). Using the Minitab program, the effect of the parameters on the joint was analysed. The maximum value of the shear force was (1587 N) at 1.5 min. time and 1340 rpm rotational speed. The minimum shear force was (589 N) at 1 min. time and 920 rpm rotational speed. The joints which were tested failed by an interfacial shear with a ductile fracture of the polymer side. The process of joining mechanism occurred through a mechanical interlocking between the molten polymer and the surface of the AA 1050 aluminium specimen, cohesive and adhesive. The average thickness for the joint of the tested specimens was 4µm.

Downloads

References

Hamzah, Mahmood Mohammed, and Sabah Khammass Hussein. "Effect of Surface Pretreatment on Hot Press Lap joining of High Density Polyethylene to Stainless Steel Alloy AISI 304L." IOP Conference Series: Materials Science and Engineering. Vol. 745. No. 1. IOP Publishing, 2020, DOI 10.1088/1757-899X/745/1/012058.

Barrak, Osamah Sabah, et al. "Joining of double pre-holed aluminum alloy AA6061-T6 to polyamide PA using hot press technique." IOP Conference Series: Materials Science and Engineering. Vol. 881. No. 1. IOP Publishing, 2020, DOI 10.1088/1757-899X/881/1/012062.

Mostafapour, A., and F. Taghizad Asad. "Investigations on joining of Nylon 6 plates via novel method of heat assisted friction stir welding to find the optimum process parameters." Science and Technology of Welding and Joining 21.8, 660-669. 2016, https://doi.org/10.1080/13621718.2016.1169669.

Bergmann, Jean Pierre, and Martin Stambke. "Potential of laser-manufactured polymer-metal hybrid joints." Physics Procedia, 39, 84-91. 2012, https://doi.org/10.1016/j.phpro.2012.10.017.

Hussein, Sabah K., Abdulmuhssan N. Mhessan, and Mustafa A. Alwan. "Hot press joining optimization of polyethylene to aluminium alloy AA6061-T6 lap joint using design of experiments." Engineering Journal, 21.7, 157-169, 2017, https://doi.org/10.4186/ej.2017.21.7.157.

Lambiase, Francesco, and Dae-Cheol Ko. "Two-steps clinching of aluminum and carbon fiber reinforced polymer sheets." Composite Structures, 164, 180-188, 2017, https://doi.org/10.1016/j.compstruct.2016.12.072.

Osamah Sabah Barrak, Osamah Fattah Taresh, Mahmood Mohammed Hamzah, and Rusul Ahmed Shakir, “An Investigation of Joining Polyamide (PA) to Stainless Steel AISI 316L by Hot Press Process”, JT, vol. 5, no. 1, pp. 114–121, Apr. 2023, https://doi.org/10.51173/jt.v5i1.1280.

Amancio‐Filho, S. T., and J. F. Dos Santos. "Joining of polymers and polymer–metal hybrid structures: recent developments and trends." Polymer engineering & science, 49.8, 1461-1476, 2009, https://doi.org/10.1002/pen.21424.

Goushegir, S. M., J. F. Dos Santos, and S. T. Amancio-Filho. "Friction spot joining of aluminum AA2024/carbon-fiber reinforced poly (phenylene sulfide) composite single lap joints: microstructure and mechanical performance." Materials & Design (1980-2015), 54, 196-206, 2014, https://doi.org/10.1016/j.matdes.2013.08.034.

Barrak, Osamah Sabah, Mahmood Mohammed Hamzah, and Sabah Khammass Hussein. "Friction Stir Spot Welding Of Pure Copper (C11000) With Pre-Holed Threaded Aluminum Alloys (AA5052)." Journal of Applied Science and Engineering, 26.8, 1103-1110, 2022, https://doi.org/10.6180/jase.202308_26(8).0006.

Wang, Hongyang, Kai Yang, and Liming Liu. "The analysis of welding and riveting hybrid bonding joint of aluminum alloy and polyether-ether-ketone composites." Journal of Manufacturing Processes, 36, 301-308, 2018, https://doi.org/10.1016/j.jmapro.2018.10.031.

Huang, Y., Meng, X., Xie, Y., Li, J., & Wan, L., "New technique of friction-based filling stacking joining for metal and polymer." Composites Part B: Engineering, 163, 217-223, 2019, https://doi.org/10.1016/j.compositesb.2018.11.050.

Bragança, I. M. F., Silva, C. M. A., Alves, L. M., & Martins, P. A. F, "Lightweight joining of polymer and polymer-metal sheets by sheet-bulk forming." Journal of Cleaner Production, 145, 98-104, 2017, https://doi.org/10.1016/j.jclepro.2017.01.049.

Yusuke Kajihara, Yuta Tamura, Fuminobu Kimura, Gota Suzuki, Naotake Nakura, Eiji Yamaguchi, “Joining strength dependence on molding conditions and surface textures in blast-assisted metal-polymer direct joining”, Manufacturing Technology, Vol. 67, pp. 591-594, 2018, https://doi.org/10.1016/j.cirp.2018.04.112.

Anjal R. Patel, Dhrupal J. Kotadiya, Jaydeep M. Kapopara, Chirag G. Dalwadi Nicky P. Patel, H. G. Rana, “Investigation of Mechanical Properties for Hybrid Joint of Aluminium to Polymer using Friction Stir Welding (FSW)”, Materials Today: Proceedings, Vol.5, pp. 4242–4249, 2018, https://doi.org/10.1016/j.matpr.2017.11.688.

Aghajani Derazkola, H., Khodabakhshi, F., Simchi, A., “Friction-stir lap-joining of aluminium-magnesium/poly-methyl-methacrylate hybrid structures: thermo-mechanical modelling and experimental feasibility study”, Sci. Technol. Weld. Joining, Vol. 23, pp.35–49, 2018, https://doi.org/10.1080/13621718.2017.1323441.

Kubit, Andrzej, Dawid Wydrzynski, and Tomasz Trzepiecinski. "Refill friction stir spot welding of 7075-T6 aluminium alloy single-lap joints with polymer sealant interlayer." Composite Structures, 201. 389-397, 2018, https://doi.org/10.1016/j.compstruct.2018.06.070.

ANSI/AWS C1.1M/C1.1:2012, Recommended Practices for Resistance Welding, American Welding Society.

American Society for Testing and Materials (ASTM), 2004 Standard Methods of Tension Testing of Metallic Materials, ASTM E 407- 99, Annual book of ASTM standards, 3(1).

Liu, H. J., Y. C. Chen, and J. C. Feng. "Effect of zigzag line on the mechanical properties of friction stir welded joints of an Al–Cu alloy." Scripta Materialia, 55.3, 231-234, 2006, https://doi.org/10.1016/j.scriptamat.2006.04.013.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Osamah Sabah Barrak, Mahmood Mohammed Hamzah, Ali Safaa Ali, Slim Ben-Elechi, Sami Chatti, Wasaq Haider Moubder, Ruba Rasool Radhi, Arfan Ali Ahmad

This work is licensed under a Creative Commons Attribution 4.0 International License.